Helping Australian manufacturers secure market advantage through specialised, versatile manufacturing.

Industry 5.0—which combines creative human cognition with technological advances such as robotics, AI, big data and additive manufacturing (3D printing)—is upon us. This new era of machine-assisted collaboration is transforming the manufacturing sector, enabling early adopters to secure market advantage by creating entirely new products, machines, materials and processes.

Advanced manufacturing is Australia’s ticket to ensuring it remains competitive in a global market of mass productions and low labour costs. It might be capturing corporate knowledge to seamlessly and efficiently train an increasingly transient workforce, finding clever ways of analysing the massive volumes of data to improve efficiency, developing novel materials and technologies, or incorporating robotics and automated solutions to streamline manufacturing processes. This will not only improve work efficiency and decrease manufacturing costs but make workplaces safer.

One of the advantages of advanced manufacturing is its versatility. By simply programming new parameters, we can construct something completely different with the same technology, allowing the bespoke production of complex, customised components.This has implications for a vast number of industries, from defence to the production of medical devices. Medical implants, for example, are typically mass produced with common size choices such as “small”, “medium” or “large”. But with a quick digital scan, a local manufacturer could produce a bespoke implant that fits a patiently perfectly.

Under our theme of “Advanced manufacturing and materials”, we are bringing together research leaders in engineering, science, business, design and planning to unite previously fragmented processes and technologies.

Our vision is to partner with industry and government to:

- Provide concept-to-production demonstration capabilities, including advanced pre- and post-processing of materials by using advanced manufacturing technologies and automation.

- Streamline the manufacturing process through the creation of digital twins, enabling real-time iterative design to improve efficiency and reduce costs.

- Incorporate systems engineering, computer modelling and world class design to develop new products and materials ranging from ‘green steel’ to drug delivery systems.

- Develop sophisticated models using advanced sensors and data analytics that assess reliability and performance of materials and accurately predict maintenance requirements.

- Develop augmented, virtual and extended reality solutions to enhance training, enable remote maintenance and retain corporate knowledge for transitioning workforces.

- Up-skill the existing workforce through micro-credentials and training that enhances use of cutting-edge digital science and technology.

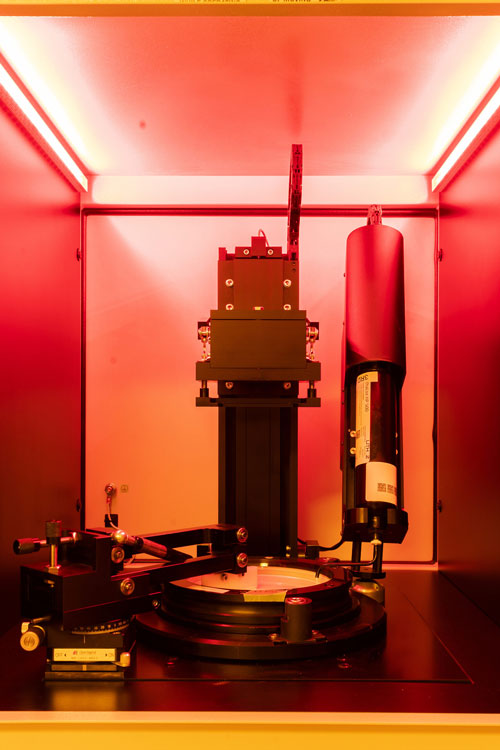

Our specialist facilities:

The Sydney Manufacturing Hub

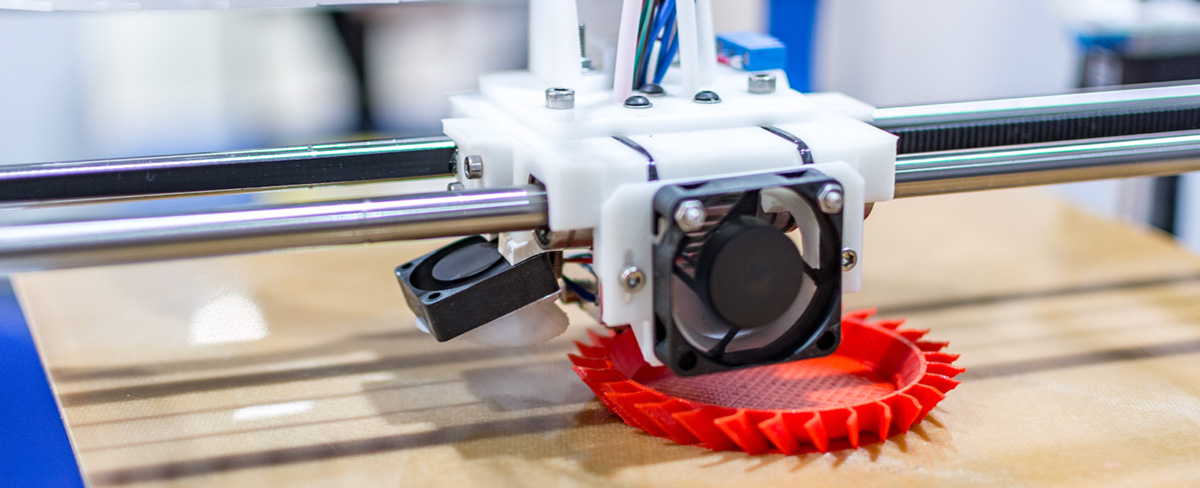

State-of-the-art equipment and knowledge in additive manufacturing to fabricate components in metals, ceramics, polymers and composites. A large range of post-processing tools are also available to optimise manufactured component performances.

Current Projects

-

Creating the next generation of tungsten carbide-cobalt hard metals

Tungsten carbide-cobalt metals are among the most widely used metals in the world, with a…

-

3D printing to enable new, customisable advanced alloys

Additive Manufacturing is using 3D printers, data and computer-aided design to create completely customisable parts…

-

State of the art hub to bolster Australia’s competitive advantage

Advanced manufacturing accounts for half of Australia’s manufacturing output and is one of the fastest…