Category: Current projects

News & events

-

Human intelligence in AI loop

In this project, we will investigate how to introduce human intelligence in the loop when…

-

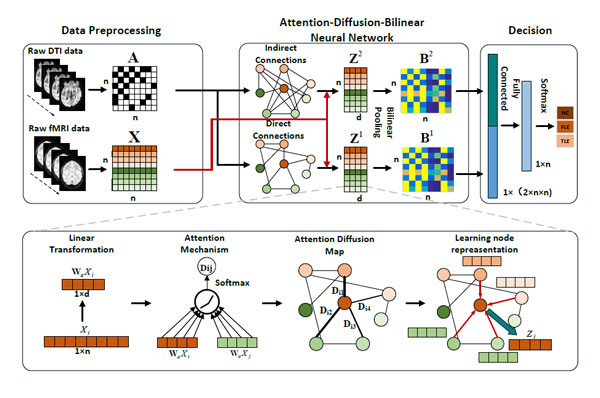

Imaging analysis and AI

In this project, we will focus on cohesively developing advanced AI technologies to revolutionise imaging-based…

-

SoilWaterNow: Soil water nowcasting for the Australian grains industry

In this project funded by the GRDC we are developing a modular and scalable framework…

-

Field robotics

The aim of this project is to develop autonomous systems capable of operating continuously on…

-

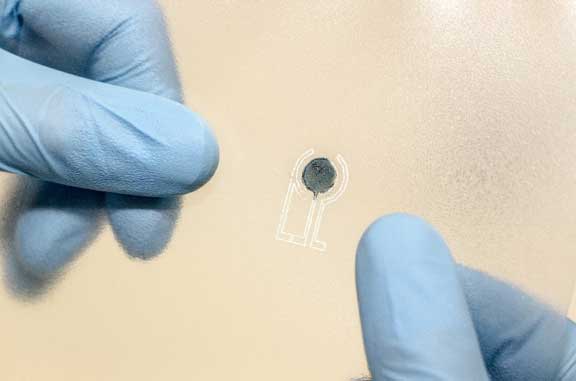

Monitoring our food supply

In this project we are developing novel sensors to monitor food quality, safety, and authenticity…

-

Creating the next generation of tungsten carbide-cobalt hard metals

Tungsten carbide-cobalt metals are among the most widely used metals in the world, with a…

-

3D printing to enable new, customisable advanced alloys

Additive Manufacturing is using 3D printers, data and computer-aided design to create completely customisable parts…

-

State of the art hub to bolster Australia’s competitive advantage

Advanced manufacturing accounts for half of Australia’s manufacturing output and is one of the fastest…

-

Medical devices and technology

—

Enormous advancements in health care can provide correspondingly enormous impacts in Defence applications. Our research…

-

Materials design and modelling

—

Our materials design and modelling capabilities span the full range of length-scales from individual atoms…

-

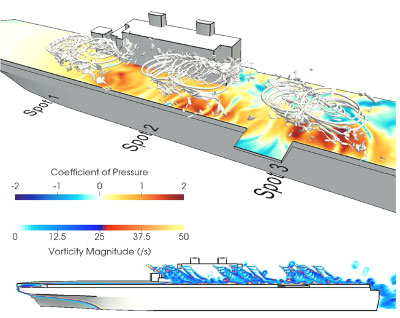

Computational design and engineering

—

We have longstanding collaborations with defence in developing and translating state of the art computational…

-

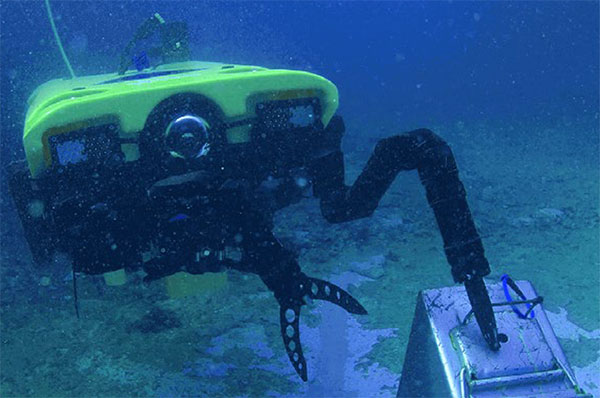

Robotics and machine learning

—

The Australian Centre for Field Robotics (ACFR) is dedicated to the research, development and dissemination…